3 Most Popular Abrasives Tools Types & Industrial Applications You Must Know

What are abrasives?

Abrasives are tools made with a material of certain hardness that is used for shaping or giving a fine finish to the material that is rubbed against it aka workpiece. The sharp, hard material used is called an abrasive.

What are abrasive tools made of?

Abrasive tools are made of many different abrasive grains and other materials. The grains used are very hard so that they can be used to give a shape, fine finish, or polish to the other materials. Abrasive tools can be used for working on gemstones, glass, ceramic, stone, steel, and other metal or nonmetallic materials.

Abrasives in the ancient times

Tracing back to the ancient cultures that sprawled modern-day Egypt, Greece & India, notable evidence of abrasive grinding was found. Greeks extracted Quartz, an abundant mineral at that time, along with sand, and flint and were used to grind wood and metal substrates. Early civilizations harvested sharkskin because of the abrasive properties its scaly dermal texture has. The uniform configuration of scales acted as an abrasive material similar to sandpaper.

Advancements in Abrasives

Centuries of breakthroughs witnessed advancements in abrasives. The Industrial Revolution fostered advancements in abrasive performance. The demand for higher abrasive performance led to the development of synthetic abrasives, often referred to as manufactured abrasives.

Classification of Abrasives

As mentioned earlier, abrasive materials are hard crystals that are either found in nature or manufactured. Thus, abrasives can be classified as:

- NATURAL ABRASIVES

- MANUFACTURED/SYNTHETIC ABRASIVES

Natural Abrasives are the minerals that are found in natural deposits and can be mined and processed for use with little alteration.

Examples: Calcite, Diamond, Iron oxide, Sand, Sandstone, and powdered feldspar.

Synthetic Abrasives are formed after considerable processing of raw materials or chemical precursors.

Examples: Borazon, ceramic, aluminum oxide, dry ice, glass powder, steel abrasive, silicon carbide, and slags.

Furthermore, there are 3 main variables for classifying these natural and synthetic abrasive tools. The 3 variables are hardness, composition structure, and grain type. Let us explore these different types of abrasive tools.

A. Classification based on hardness

A succinct classification of abrasive tools can be done mainly by their degree of hardness. The abrasive must be harder than the material it is to grind, polish, or remove.

- Diamond is the hardest mineral naturally available on the Earth. There are also other materials of both natural and synthetic origin, such as silicon carbide, corundum, and zirconium. These do not reach the same hardness as the diamond, but they are very close to it.

- With hardness second to diamond and no equivalent natural mineral, CBN is produced synthetically at a high temperature, a high-pressure process similar to synthetic diamond. Used as an abrasive mineral, a hard coating material, and machining insert, CBN’s primary value in grinding is for machining of ferrous materials which chemically react with diamond.

Natural Abrasives

industrial diamond |

corundum |

emery |

garnet |

flint |

quartz |

pumice |

talc |

Synthetic Abrasives

| synthetic diamond |

| boron nitride (cubic) |

| boron carbide |

| silicon carbide |

| alumina |

B. Classification based on composition structure

Depending on composition structure, there are 3 types of abrasives:

- Conventional Bonded Abrasives

- Superhard Abrasives or Superabrasives

- Coated Abrasives

1. Conventional bonded abrasives

An abrasive grain and bond are the vital characteristics of any abrasive tool. Bonded abrasives, such as those in grinding wheels, are made up of grains that are held together by a fixative material called a bond. These abrasives are composed of abrasive material, bond, and fillers. The abrasive grains for Conventional Bonded Abrasives can be an aluminum oxide or silicon carbide.

2. Superhard Abrasives or Superabrasives

When it comes to super abrasives, there are two types to be aware of: Diamond and CBN(Cubic Boron Nitride).

The body of diamond and CBN grinding wheels is made of steel or aluminum. The working layer is where you will find abrasive grains.

- Diamond grinding wheels are used to sharpen carbide cutting tools, cut ceramics, and polish granite.

- CBN is the next best choice in terms of hardness after diamond but doesn’t react with ferrous metals. As a result, a lack of reaction reduces wear on the grinding grains and increases efficiency. For this reason, CBN is the best choice for grinding iron metals and alloys.

3. Coated Abrasives

Coated abrasives are composed of abrasive grains that are built onto a cloth or paper backing then formed into a sanding belt, abrasive disc, abrasive roll, abrasive sheet, and flap-wheel, etc.

C. Classification based on grain type & color

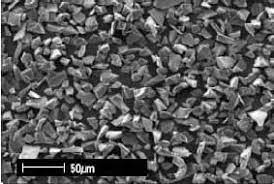

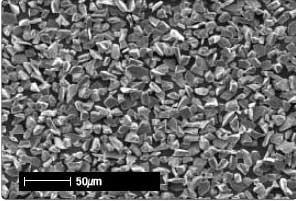

The two types of grains are:

- Sharp shaped grains

Compact-shaped grains

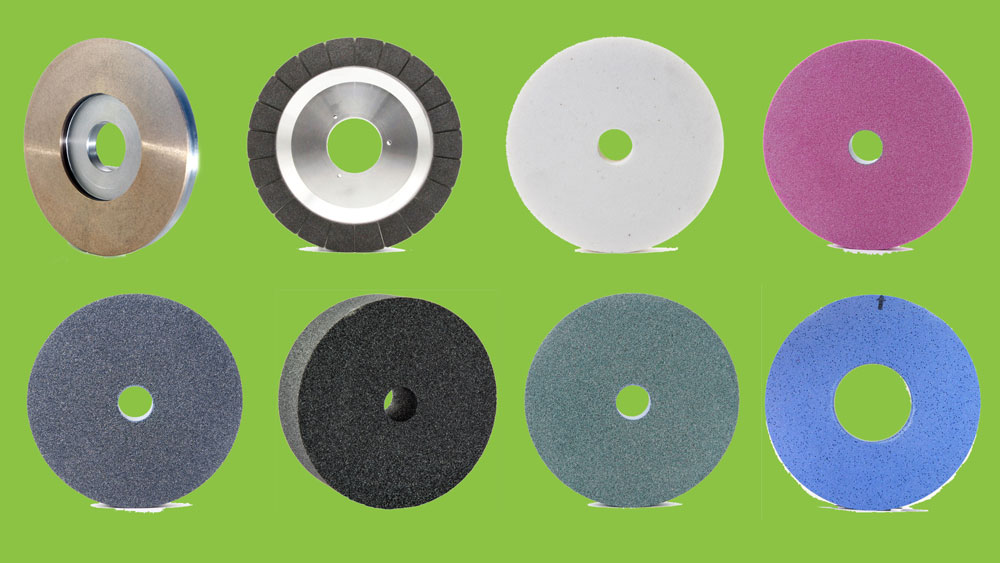

These different shaped abrasive grains have different colors. Take a look at the table below:

Abrasive Grain |

Associated Color |

Diamond |

Golden |

CBN |

Black |

Aluminum oxide |

White |

Aluminum oxide fused with chrome oxide |

Pink |

Low titania brown fused aluminum oxide |

Brown |

White Aluminum with ferric oxide |

Orange |

Silicon Carbide |

Black/Green |

Seeded Gel |

Blue |

Different abrasive instruments correspond to different types of processing and depending on the abrasive shape they are categorized into grinding wheels, polishing wheels, cutting wheels, and drilling tools. Choosing the right abrasive shape is essential for working a surface.

1. Cutting Wheels

A cutting wheel is a thin reinforced grinding wheel made with either metal, resin, or electroplated bonds. It is used for fast and comfortable cutting of materials like metal, stone, concrete, etc. These wheels are also known as parting or self-sharpening wheels. They are typically made with conventional abrasives. Based on the shape, size, type, and grit-number of abrasives, users can decide which cut-off wheel is suitable for the workpiece.

2. Grinding Wheels

Grinding wheels appear round in shape and contain abrasive grains. These abrasive grains act as grinding tools, removing material from a workpiece to shape and refine it. The main aspects of a grinding wheel are diameter, thickness, and center hole. Grinding wheels are useful in many grinding and machining operations.

3. Polishing Wheels

The purpose of a polishing wheel is to give the metal a soft, smooth surface. Metal can get damaged over time, creating a jagged, rough texture. The abrasive properties of a wheel help to buff this down so it becomes smoother. This is achieved by using the wheel in combination with an abrasive compound.

4. Drilling Tools

Drilling wheels are mainly used for hole processing. The most popular diamond drilling tool is the diamond thin wall core drill bit. These diamond core drill bits have a thin wall in comparison with other standard diamond core drills. The thin wall allows for a more precise cut with a better surface finish and less chipping. They are used on delicate, hard materials such as optical glass, watch glass, sheet glass, thin glass, thin slices of stone, or any stone that is 6.5 or below on the Moh’s scale of hardness. They are manufactured with a precision outer diameter for drilling a hole but the thin wall also allows for precision extraction of a core.

5. Mounted Points

Mounted points are nothing but small grinding wheels bonded over a mandrel. It comes in different shapes and sizes, abrasive grains, rubberized, and felt material. It is suitable for internal grinding, irregular shape rust removal, or deburring. It is combined with a die grinder, straight shaft grinder, or hand-held rotary tools.

6. Sharpening Stones

Sharpening stones are rectangular and are used to sharpen the edges of steel tools. They can also be called dressing stones, honing stones, etc. They can also be made of diamond, CBN, aluminum oxide, and silicon carbide.

Applications of Abrasives

- Buffing

- Honing

- Drilling

- Grinding

- Polishing

- Cutting

- Sharpening

Industrial Uses of Abrasives

Industries use abrasives in basic forms:

- Cleaning of surfaces and the coarse removal of excess material, such as rough off-hand grinding in foundries.

- Bonded to form solid tools such as grinding wheels, cylinders, rings, cups, segments, or sticks.

- Shaping, as in the form of grinding and tool sharpening.

- Coated on backings made of paper or cloth in the form of sheets (such as sandpaper), strips, or belts.

- Sizing, primarily in precision grinding

- Separating, as in cut-off or slicing operations.

- Loose; held in some liquid or solid carrier as for polishing or tumbling, or propelled by the force of air or water pressure against a work surface (such as sandblasting for buildings).

Conclusion

The motive of this article is, to sum up, the categorization of abrasives and simplify its classification. It gives you a brief idea of each abrasive & its industrial uses so that it becomes easier to relate it with your application. It will not only save your time but also the efforts that you put into research work for finding the suitable abrasive type. Also, you can find these abrasives online of high-quality brands at affordable price rates. To know more kindly click here.